Keep up with the latest from Atexor! Contact us at any time to find out more about our custom Ex-lighting solutions.

A bright outlook for LED

Posted on: 25.4.2019The LED EX-lighting market is set to increase in the next four years

With the rapid development of LED advanced technology, LED EX-lighting solutions are becoming more and more popular. In fact, according to market experts, Absolute Reports, the global Hazardous Location LED Lighting market is projected to increase by 11% by 2023 and the increasing demand for energy-efficient lighting is set to drive this growth market to an estimated value of $92.40 billion by 2022.

As a leading EX-lighting manufacturer, Atexor fully understands the benefits LED can bring to our customers’ businesses and as a result we have a robust strategy in place to support this increased demand to ensure we continue to support our customers as safely, cost effectively and efficiently as possible.

In line with market trends, we are already experiencing a rise in LED lighting requests as customers look to replace compact fluorescent lamps with energy-efficient LED lamps across their facilities. Over time, the older generation EX-lighting solutions will be slowly phased out, primarily because LED solutions offer a longer working life and consume less energy but more importantly, improve your environmental footprint as well as the safety of your employees.

Why LED?

It is common knowledge that LED lighting is far more environmentally friendly because less electricity is required, and the emission of greenhouse gases is significantly reduced. Not only does using LED solutions improve our planet, but by using less electricity, business costs are also reduced. Furthermore, the light output generated from advanced LED lighting solutions provides enhanced illumination and widespread quality light which also contributes to improving working conditions and making hazardous environments safer for employees. It is important however that when choosing any LED EX- lighting solution, it complies and is certified to Op-is standard. You can read more on Op-is here.

LED benefits include:

- More environmentally friendly

- Reduced energy costs

- Improved light source

- Safer working conditions

- Reduced ongoing maintenance

- More reliable and durable

- Improved temperature range

- Longer product life span

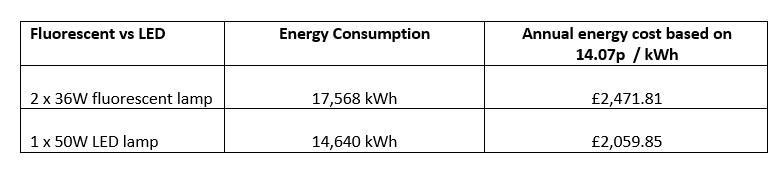

Operational cost savings are most certainly seen when using LED EX-lighting solutions. Based on 100 LED lamps vs 100 fluorescent lamps being used continuously for 4 months, the following comparisons have been made:

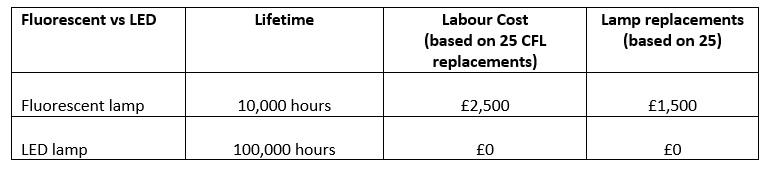

Running costs alone with LED clearly shows the significant savings to be had for businesses. But the savings don’t end there. LED solutions also offer a longer product life span and practically speaking do not require any maintenance, due to their strong mechanical endurance. Compact Fluorescent Lamp (CFL) luminaires, however, are more fragile and do break when used in harsh conditions. As a result, further estimated cost savings can be calculated for lamp replacements and labour costs as below:

Already based on a small number, saves are clear therefore when you consider the volume of luminaires used at an industrial site, the maintenance cost savings will be huge in the long run.

A bright outlook

Many of our customers are continually looking to stay ahead technologically as well as align with the global environmental movement towards taking more responsibility to reduce gas emissions. As a result, they are beginning to install LED lighting solutions across their industrial plants. Investment is undoubtedly required; however, the long-term benefits makes this extremely worthwhile when you consider escalating energy prices which is a major cost for industrial lighting applications as well as the other benefits outlined above when using LED solutions. A thorough return on investment calculation should quickly diminish these concerns.

In line with the changing market, from 30th June 2019, Atexor will no longer manufacture (CFL) luminaires. We feel the time is right from an environmental and technological perspective to support our client base with the safest and most innovative solutions to continue improving their business. We will of course continue to support to supply spare parts for CFL luminaires in accordance with the ATEX directive. However, as time goes by, we believe the majority of our customers, will have made the move to LED EX-lighting products.