Critical elements in confined space risk assessment

By Tuomas Seilo

Over the course of my 15 years working with temporary Ex-lighting, I have come to compare the confined spaces at petrochemical plants with a modern passenger jet. As humans by nature do not belong 37,000 ft in the air, they surely do not belong in industrial confined spaces. Maintenance of these spaces is like flying an airplane without autopilot.

Just as airplane manufacturers need to ensure the safety of passengers, a series of precautions need to be taken and training completed before any job in a confined space may be even started. Why? Because industrial maintenance of confined spaces always entails great risks. Bringing even highly trained personnel, air and power supplies to an area where they do not belong significantly increases health and safety risks, especially when explosion-hazardous substances and gases are present.

One part of the risk assessment is selecting proper equipment. A typical view of many operators seems to be that “a piece of equipment with an Ex-label on it is enough”. Well, we all know it is not as simple as that. However, it is the duty of equipment manufacturers to spread the word about the latest safety standards and educate people how to perform their jobs safer than before.

Four essential safety elements

I list here four safety elements which hopefully gives you some food four thought when preparing your next risk assessment of confined space entry.

1) Low-voltage

Equipment that uses voltages below 50VAC protect you from electrocution should an electrical failure occur. Using 110VAC or 230VAC equipment in confined space is without exception more dangerous that low-voltage equipment.

2) Truly portable ATEX-equipment

ATEX-certified equipment with an explicit ’Portable equipment‘ distinction seldom have restrictions on use such as disconnecting the power supply when moving the equipment around.

Ex equipment without this distinction is not considered ‘portable’, but rather only ‘transportable’ – there are restrictions on how the equipment can be moved.

Imagine a maintenance person squeezing himself out of a tank manhole, disconnecting the equipment, crawling back into the tank again, moving the equipment to then next location, and then going back out, and again back in just to power up the equipment. Needless to say, this is an unpleasant waste of time – and unlikely to happen.

Portable and transportable ATEX-certified equipment have different safety characteristics that should be recognized and accounted for in the risk assessment plan.

3) Light

As long as it is humans who are doing the maintenance in dark and challenging environments, proper lighting is needed. This does not necessarily mean you need to provide the maximum amount of light possible, but rather assess aspects like ideal light temperature, sufficient diffusion of light and light color.

It is not just about workers’ eyes, but explosion-protection as well. Today’s powerful LEDs can easily become an ignition source if they are not designed to account for optical radiation. Inherently safe optical radiation, or ‘op is’, has become a hot topic for modern LEDs used in hazardous areas, no pun intended. Make sure ’op is‘ is part of the ATEX certification of the equipment.

The better the light is the better job result, and less accidents you can expect.

4) Emergency function

What about when a power failure kicks in? All of a sudden you are standing in a patch black vessel without any light or indication where you should go. If there is a site alarm and everyone needs to be evacuated quickly, also those in the vessel, which manhole should they use to exit? When planning temporary lighting, why not choose work lights with an emergency function (EM-function) and EXIT-signs as well?

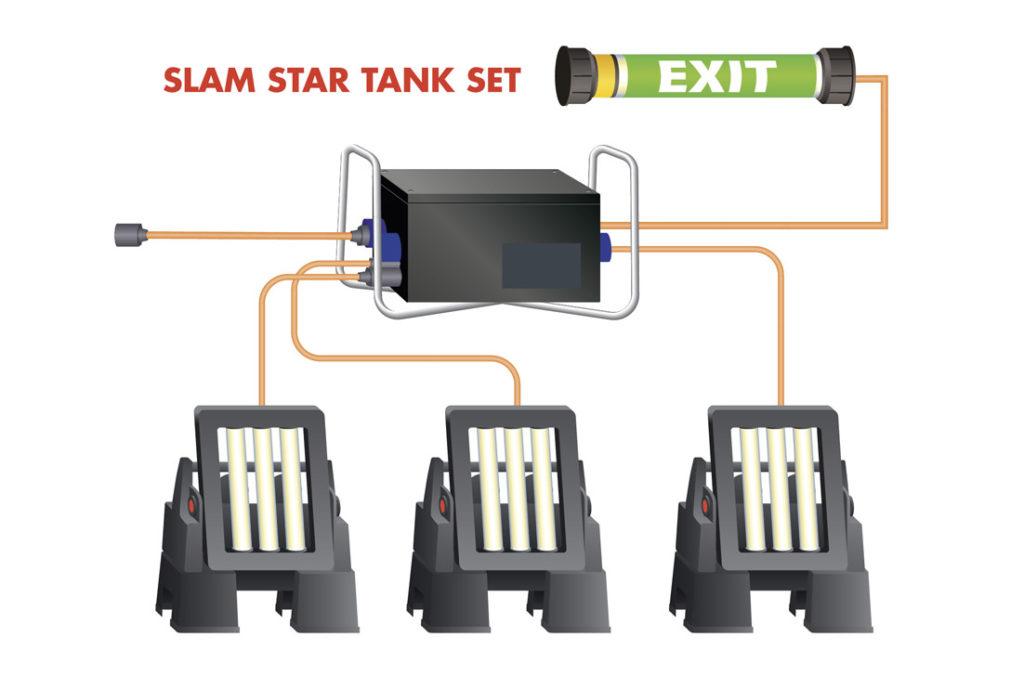

Lighting designed for confined spaces

We have been designing and manufacturing different types of SLAM® Tank Sets manufactured by Atexor for oil and petrochemical customers for decades.

If you would like to learn more about the advanced safety features of SLAM® Tank Sets and other solutions for confined space, please visit our product pages or contact me directly.