Ex Zone

Ex Zone

Explosion Hazardous Areas are divided into zones according to risk probabilities. Within the European Union, these are defined by IEC/EN standards (IEC/EN 60079-10-1 or 2) as directed by ATEX.

There are three zones for gas: Zone 0, Zone 1 and Zone 2. And there are three corresponding zones for dust: Zone 20, Zone 21 and Zone 22. Put simply, the 0-zones (0 and 20) are highest risk probability, and 2-zones lowest (2 and 22).

How the risks are classified is a bit more complex. One Hazardous Area can have several different zones. Risk factors include how long the explosion hazard is present and how far the source of the hazard is from the area in question.

With the zone classifications, there is a big difference between Zones 0-1 and Zone 2. The demands on Ex-rated products for Zone 2 are significantly lower. They are so low that you could almost say Zone 2 products are unregulated. There is no 3rd party testing requirement, for example.

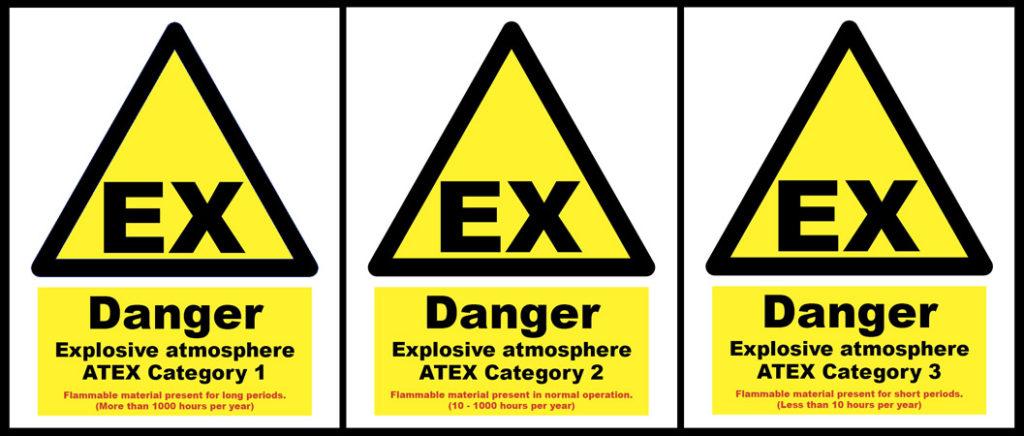

The Ex Zones are further classified into Categories according to the IEC/EN standards. The Category classification is used on equipment labels and may also be on Ex-area signs, as you can see below:

The Category classification indicates both the Ex Zone and Equipment Protection Level (EPL) for the are:

- Category 1 – equipment can be used in Zone 0 or 20 and must have EPL a

- Category 2 – equipment can be used in Zone 1 or 21 and must have EPL b

- Category 3 – equipment can be used in Zone 2 or 22 and must have EPL c

Category 1 equipment can also be used Category 2 and 3 areas, while Category 2 equipment can abe used in Category 2 and also Category 3. Category 3 equipment must only be used in Category 3 areas. And naturally, equipment with Category 1, 2 or 3 classification can be used in non-hazardous applications.